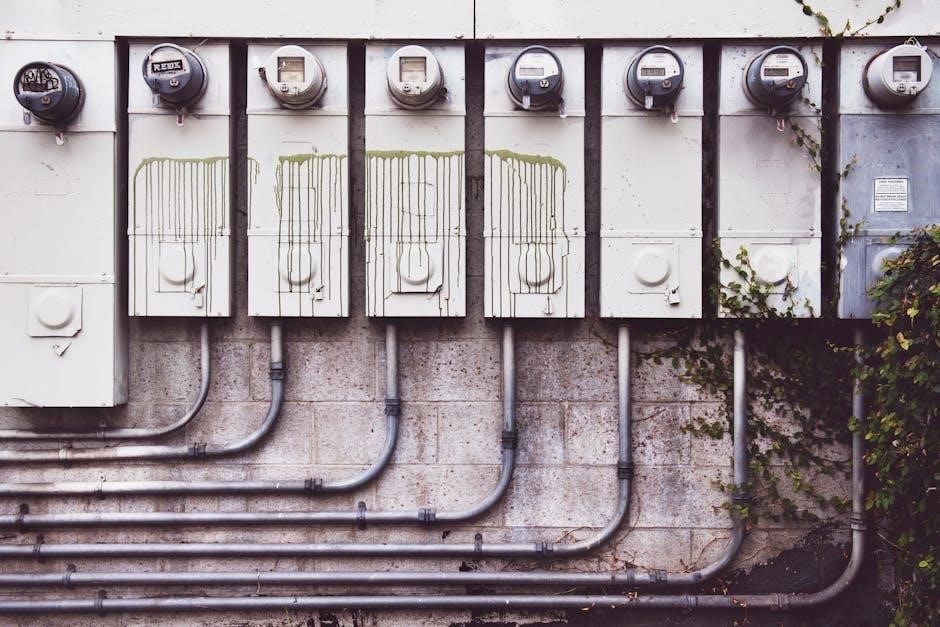

The Kenworth T880 wiring diagram is a detailed schematic guide essential for understanding the truck’s electrical system. It provides a visual representation of wire connections, circuits, and components, aiding in diagnostics and repairs. These diagrams are crucial for technicians and drivers to identify and fix issues efficiently, ensuring optimal vehicle performance and safety.

1.1 Overview of the Kenworth T880

The Kenworth T880 is a versatile and durable Class 8 truck designed for both on-highway and vocational applications. Known for its reliability, it features a robust engine and transmission system, making it a popular choice for heavy-duty tasks. The T880 is equipped with advanced technology and ergonomic design, ensuring driver comfort and efficiency. Its electrical system is complex, requiring detailed wiring diagrams for proper maintenance and repairs. This overview highlights the T880’s key features and the importance of understanding its electrical framework.

1.2 Importance of Wiring Diagrams in Truck Maintenance

Wiring diagrams are indispensable for maintaining the Kenworth T880, as they provide a clear map of the electrical system. These diagrams help technicians identify circuits, connectors, and components efficiently. By referencing a wiring diagram, issues like faulty fuses or short circuits can be diagnosed quickly, reducing downtime. They are also essential for installing aftermarket accessories correctly. Without a wiring diagram, troubleshooting and repairs become challenging, potentially leading to safety hazards or further damage. Thus, they are a cornerstone of effective truck maintenance and repair processes.

Sources for Kenworth T880 Wiring Diagrams

Kenworth T880 wiring diagrams are available through official Kenworth manuals, online PDF resources, and third-party repair guides. These sources provide detailed electrical system schematics for accurate troubleshooting and repairs.

2.1 Official Kenworth Manuals and Documentation

Official Kenworth T880 manuals are the most reliable source for wiring diagrams. These manuals, available as PDFs, contain detailed schematics and explanations of electrical systems. They are designed for professionals and DIY enthusiasts, ensuring accurate repairs. The manuals cover all components, from lighting to brakes, and are updated regularly to reflect model changes. Accessing these through Kenworth’s official website or authorized dealers guarantees authenticity and completeness, making them indispensable for troubleshooting and maintenance tasks.

2.2 PDF Resources Available Online

PDF resources for Kenworth T880 wiring diagrams are widely available online, offering convenient access to detailed electrical schematics. These documents are often shared through forums, repair communities, and file-sharing platforms. They provide comprehensive guides for diagnostics and repairs, covering various systems like lighting, brakes, and trailer connectivity. PDFs are favored for their portability and ease of use, allowing technicians to reference them on tablets or laptops during maintenance. However, users should verify the source to ensure accuracy and avoid outdated or incorrect diagrams.

2.3 Third-Party Repair Manuals

Third-party repair manuals are an excellent resource for Kenworth T880 wiring diagrams, offering detailed schematics and troubleshooting guides. These manuals are often created by experienced technicians and cover a wide range of electrical systems. They include comprehensive instructions for identifying and resolving common issues, such as faulty fuses or short circuits. Additionally, they provide insights into advanced diagnostics using tools like multimeters and oscilloscopes, making them invaluable for both novice and experienced mechanics. These manuals are widely available online and can be downloaded in PDF format for easy reference.

Understanding the Wiring Diagram

Understanding the Kenworth T880 wiring diagram involves identifying components, recognizing symbols, and interpreting color codes to diagnose issues like faulty switches or connectors effectively.

3.1 Key Components and Symbols

Key components in the Kenworth T880 wiring diagram include legends, connectors, and fuses. Symbols represent elements like switches, lamps, and relays, while color codes indicate wire functions. Ground points and power sources are clearly marked, aiding in troubleshooting issues like blown fuses or short circuits. Understanding these components and symbols is crucial for diagnosing electrical problems, such as faulty switches or connectors, ensuring safe and effective repairs; This knowledge helps technicians pinpoint issues quickly, reducing downtime and improving overall vehicle reliability.

3.2 Color Coding and Wire Identification

Color coding in the Kenworth T880 wiring diagram helps identify wire functions quickly. Red wires typically indicate power sources, while black wires are often ground connections. Yellow wires may signify signal or control circuits. Understanding these codes is crucial for diagnosing issues like short circuits or faulty connectors. Wire identification is further enhanced by labels and gauge sizes, which denote current capacity. Properly interpreting these elements ensures accurate troubleshooting and repairs, reducing the risk of electrical system damage; This system is essential for maintaining the truck’s reliability and performance.

3.3 Common Diagram Layouts

Kenworth T880 wiring diagrams often feature standardized layouts, including side, top, and rear views, to simplify understanding. These diagrams typically organize circuits by system, such as lighting or brakes, making it easier to trace connections. Components like fuses, relays, and connectors are highlighted for quick identification. The layouts may also include color-coded keys and symbols, ensuring clarity. This structured approach helps technicians pinpoint issues efficiently and perform repairs accurately, reducing downtime and ensuring safety.

Tools Required for Wiring Diagram Analysis

A multimeter, wire strippers, and circuit testing kits are essential for analyzing Kenworth T880 wiring diagrams, ensuring accurate diagnoses and repairs of electrical systems.

4.1 Multimeter for Voltage Testing

A multimeter is a critical tool for voltage testing in Kenworth T880 wiring diagrams, enabling technicians to measure voltage, current, and resistance. It helps identify faulty circuits and components by comparing readings to the wiring diagram’s specifications. This ensures accurate troubleshooting of electrical issues, such as open circuits or short circuits. Regular use of a multimeter can prevent costly repairs by catching problems early. Always refer to the wiring diagram to understand which wires to test and expected voltage levels for precise diagnostics and maintenance.

4.2 Wire Strippers and Connectors

Wire strippers and connectors are essential tools for working with the Kenworth T880 wiring diagram. Strippers safely remove insulation from wires without causing damage, ensuring secure connections. Connectors are critical for joining wires, preventing corrosion, and maintaining electrical integrity. Properly stripping and connecting wires is vital for reliable repairs, as poor connections can lead to electrical failures. Using high-quality connectors and strippers ensures durability and minimizes the risk of future issues, aligning with the wiring diagram’s guidance for accurate and efficient repairs.

4.3 Circuit Testing Kits

Circuit testing kits are indispensable for diagnosing electrical issues in the Kenworth T880. These kits typically include tools like circuit testers, LED lights, and voltage probes. They help identify open circuits, short circuits, and faulty connections by tracing power flow through the wiring harness. By following the wiring diagram, technicians can isolate problems efficiently, ensuring accurate repairs. Regular use of these kits extends the truck’s electrical system lifespan and prevents recurring issues, making them a must-have for maintaining the T880’s optimal performance and reliability.

Troubleshooting Common Electrical Issues

Identify and resolve common electrical issues like short circuits, blown fuses, and faulty connections using the Kenworth T880 wiring diagram. This guide helps pinpoint problems efficiently.

5.1 Identifying Faulty Fuses and Relays

Use the Kenworth T880 wiring diagram to locate fuses and relays. Check for signs of wear, discoloration, or tripping. Test circuits with a multimeter to confirm power flow. Replace any blown fuses or malfunctioning relays to restore functionality. Ensure proper connections to avoid further issues. This process ensures electrical systems operate smoothly, preventing unexpected failures and maintaining safety on the road.

5.2 Diagnosing Blown Fuses in the T880

Use the wiring diagram to locate fuses and relays in the T880. Inspect for visible damage or discoloration. Test circuits with a multimeter to confirm power flow. Swap relays with identical ones to isolate faults. Replace blown fuses with the correct amperage rating. Always disconnect the battery before starting repairs. Check connectors for corrosion or wear. Addressing blown fuses promptly prevents further electrical issues and ensures safe, reliable operation of the vehicle’s systems.

5.3 Repairing Short Circuits

To repair a short circuit in the Kenworth T880, first identify the affected area using the wiring diagram. Disconnect the battery and test the circuit with a multimeter to locate the short. Inspect wires for damage or frays, and repair or replace them as needed. Ensure all connections are clean and secure. After repairs, reconnect the battery and test the system to confirm the issue is resolved. Regular inspections can help prevent future short circuits and maintain electrical system reliability.

Specific Wiring Diagrams for Key Systems

The Kenworth T880 wiring diagrams provide detailed schematics for critical systems like lighting, brakes, and trailer connections. These diagrams help technicians identify and repair system-specific issues efficiently.

6.1 Lighting System Wiring

The Kenworth T880 wiring diagram for the lighting system details connections for headlights, taillights, and auxiliary lights. It illustrates power sources, ground points, and circuit paths, aiding in troubleshooting issues like dim or non-functional lights. The diagram also highlights relay locations and fuse assignments, ensuring quick identification of faults. Regular inspection of wiring and connectors is recommended to prevent corrosion and ensure reliable operation. This section is vital for maintaining safety and visibility on the road.

6.2 Brake System Electrical Components

The Kenworth T880 wiring diagram for the brake system outlines the electrical connections for ABS modules, brake sensors, and related components. It helps diagnose issues like faulty sensors or wiring faults causing brake light alerts. The diagram details power supplies, ground connections, and signal paths, enabling precise troubleshooting. Regular inspection of these circuits ensures reliable braking performance and safety. Understanding this section is crucial for maintaining the integrity of the truck’s braking system and preventing potential accidents due to electrical failures.

6;3 Trailer Connectivity and Wiring

The Kenworth T880 wiring diagram for trailer connectivity details the 7-pin connector and its functions, ensuring proper communication between the truck and trailer. It outlines the electrical pathways for lighting, brakes, and auxiliary systems. The diagram helps identify issues like faulty connections or incorrect wiring, which can cause trailer lights or brakes to malfunction. Regular inspection of these circuits is vital for safe towing operations. Proper wiring ensures seamless integration and functionality of trailer systems, preventing accidents and ensuring compliance with safety standards.

Safety Precautions When Working with Wiring

Always disconnect the battery before starting repairs to prevent electrical shocks. Wear insulated gloves and safety goggles to protect against potential hazards. Ensure proper grounding to avoid damage.

7.1 Disconnecting the Battery Before Repairs

Disconnecting the battery is the first and most critical safety step when working with the Kenworth T880 wiring. This prevents accidental electrical shocks and power surges. Locate the negative terminal, remove the cable, and secure it away from the battery post. Never skip this step, as it ensures your safety while handling live circuits. Always refer to the wiring diagram to identify the correct battery connections and follow proper disconnection procedures to avoid damage to the electrical system.

7.2 Proper Use of Safety Gear

Wearing appropriate safety gear is vital when working with the Kenworth T880 wiring system. Always use insulated gloves to prevent electrical shocks and safety glasses to protect your eyes from debris. A multimeter is essential for testing circuits safely. Ensure all tools are rated for the voltage levels you’re working with. Proper safety gear prevents accidents and ensures compliance with industry standards. Always follow the manufacturer’s guidelines for equipment usage to maintain a safe working environment.

7.3 Avoiding Electrical Shocks

To avoid electrical shocks when working with the Kenworth T880 wiring system, always disconnect the battery before starting repairs. Use a multimeter to verify that no power is present in the circuit. Wear insulated gloves and ensure tools are properly rated for the task. Never touch live wires with bare hands, and avoid working in wet conditions. Grounding yourself and using non-conductive tools can further reduce the risk of electrical shocks. Always follow safety protocols to protect yourself from potential hazards.

Regular Maintenance Tips

Regular maintenance involves inspecting wiring harnesses for wear and cleaning corrosion from connectors. Schedule professional inspections to ensure electrical systems remain reliable and efficient.

8.1 Inspecting Wiring Harnesses

Inspecting wiring harnesses is crucial for maintaining the Kenworth T880’s electrical integrity. Use the wiring diagram to locate and identify harnesses, checking for signs of wear, cuts, or corrosion. Ensure all connectors are securely attached and free from damage. Regularly cleaning and protecting the harnesses prevents premature aging and ensures reliable performance. Replace any damaged sections promptly to avoid electrical malfunctions. This step is essential for maintaining safety and operational efficiency on the road;

8.2 Cleaning Corrosion from Connectors

Cleaning corrosion from connectors is essential for maintaining reliable electrical connections in the Kenworth T880. Use a mixture of baking soda and water or a specialized electrical cleaner to gently scrub away corrosion. A soft-bristle brush can help remove stubborn corrosion without damaging the connector. After cleaning, ensure connectors are thoroughly dried using compressed air or a clean cloth. Regularly inspecting and cleaning connectors prevents electrical issues and ensures proper system functionality. Avoid using abrasive materials that could scratch or harm the connectors.

8.3 Scheduling Professional Inspections

Scheduling regular professional inspections is crucial for maintaining the Kenworth T880’s electrical and wiring systems. Certified technicians can identify potential issues before they escalate, ensuring optimal performance and safety. Inspections should be conducted every 6 months or 50,000 miles, depending on usage. Professionals will check for worn wires, corrosion, and faulty connections, addressing them before they cause downtime. Regular inspections also help comply with safety standards and prevent unexpected failures; By prioritizing professional check-ups, you ensure the truck’s electrical system remains reliable and efficient over time.

Advanced Troubleshooting Techniques

Advanced troubleshooting involves using wiring diagrams to identify complex electrical faults. Techniques include multimeter testing, circuit analysis, and diagnostic tools to pinpoint issues efficiently and accurately.

9.1 Using a Wiring Diagram for Complex Repairs

Using a wiring diagram for complex repairs involves tracing circuits to identify faults. Start by locating the affected system in the diagram, then follow the wire connections to pinpoint potential issues. Use a multimeter to test voltage and continuity, ensuring readings match the diagram’s specifications. This method helps isolate faulty components, such as blown fuses or short circuits, allowing precise repairs. Regularly referencing the diagram ensures accuracy and prevents further damage to the electrical system.

9.2 Advanced Testing with an Oscilloscope

An oscilloscope is a powerful tool for advanced electrical system analysis. It captures waveform patterns, helping diagnose complex issues like voltage fluctuations or signal interference. Connect the oscilloscope to key circuit points as shown in the wiring diagram to monitor real-time electrical activity. This tool is especially useful for identifying intermittent faults or erratic signal behaviors that are difficult to detect with basic tools. Proper use requires understanding waveform interpretations and ensuring probe connections align with the diagram’s specifications for accurate readings.

9.3 Consulting with Experts

Consulting with experts is crucial for complex electrical issues. Experienced technicians can interpret wiring diagrams effectively, offering insights and solutions. Online forums and manufacturer support channels provide platforms to seek professional advice. Experts often share detailed troubleshooting steps and repair techniques, ensuring accurate diagnoses. Their guidance is invaluable for resolving challenging problems, especially when advanced tools or specialized knowledge are required. Leveraging expert resources enhances repair efficiency and ensures system reliability, making it a key step in maintaining the Kenworth T880’s electrical integrity.

Custom Modifications and Upgrades

Custom modifications, like adding auxiliary lighting or upgrading electrical systems, require precise wiring diagram guidance to ensure safe and effective enhancements to the Kenworth T880.

10.1 Adding Auxiliary Lighting

Adding auxiliary lighting to your Kenworth T880 enhances visibility and safety. Use the wiring diagram to identify the correct circuits for installing LED, strobe, or additional work lights. Ensure proper connections to avoid short circuits. Follow the diagram to locate power sources and grounding points. Test all connections before finalizing. This modification improves functionality and meets specific operational needs while maintaining electrical system integrity.

10.2 Upgrading Electrical Systems

Upgrading the Kenworth T880’s electrical system involves enhancing its capacity to support additional power demands. Use the wiring diagram to identify suitable circuits for high-capacity alternators or upgraded circuit breakers. Ensure compatibility with existing components to maintain system balance. Consult the diagram to locate key electrical nodes and plan the upgrade carefully. Proper installation prevents overloading and ensures reliable performance. Always test connections post-installation to verify functionality and safety.

10.3 Installing Aftermarket Accessories

Installing aftermarket accessories on the Kenworth T880 requires precise use of the wiring diagram to ensure compatibility and safe integration; Identify the correct circuits for auxiliary lighting, GPS systems, or other upgrades. The diagram helps in locating appropriate power sources and connectors. Test each connection post-installation to avoid electrical conflicts. Follow manufacturer guidelines and safety protocols to prevent damage or malfunctions. Regular maintenance checks ensure longevity and optimal performance of all added components.

Common Mistakes to Avoid

- Incorrectly splicing wires without proper insulation can cause short circuits.

- Overloading circuits with too many aftermarket accessories leads to system failures.

- Neglecting safety protocols increases the risk of electrical shocks and damage.

11.1 Incorrect Wire Splicing

Incorrect wire splicing is a common mistake that can lead to short circuits, corrosion, and open connections. Poorly connected wires may cause intermittent electrical issues, such as faulty lighting or brakes. Using improper materials, like bare wires or inadequate connectors, can exacerbate the problem. It is crucial to consult the wiring diagram for correct splicing techniques, ensuring all connections are secure and insulated. Neglecting proper methods can result in system malfunctions and potential safety hazards, emphasizing the importance of precise and durable wire connections in the Kenworth T880’s electrical system.

11.2 Overloading Electrical Circuits

Overloading electrical circuits is a critical issue that can lead to blown fuses, tripped breakers, or even fires. It occurs when too many high-power devices are connected to a single circuit, exceeding its capacity. The Kenworth T880 wiring diagram helps identify circuit limits and proper connections. Ignoring these guidelines can cause system failures and safety risks. Always consult the diagram to ensure circuits are not overloaded, and consider upgrading to higher-capacity wiring or fuses if necessary. Regular inspections can prevent such hazards and maintain optimal electrical performance.

11.3 Ignoring Safety Guidelines

Ignoring safety guidelines when working with the Kenworth T880 wiring diagram can lead to severe consequences, including electrical shocks, fires, or even fatal accidents. Always disconnect the battery before starting repairs to prevent live circuits. Proper safety gear, such as insulated gloves and goggles, should be worn at all times. Never bypass safety protocols, as this can cause irreversible damage to the electrical system. Refer to the wiring diagram for specific safety instructions tailored to the T880 model. Regular inspections and adherence to guidelines ensure a safe working environment and prevent potential hazards;

Resources for Further Learning

Video tutorials and guides provide hands-on insights into understanding and using Kenworth T880 wiring diagrams. Official Kenworth channels and platforms like YouTube offer detailed diagnostic and repair content.

12.1 Online Forums and Communities

Online forums and communities are invaluable for troubleshooting and understanding Kenworth T880 wiring diagrams. Platforms like Reddit and specialized trucking forums allow users to share experiences, ask questions, and receive advice from experienced technicians and drivers. Many threads discuss common issues, such as faulty connectors or reverse light problems, offering practical solutions and insights. These communities often include links to detailed wiring diagrams and repair guides, making them a go-to resource for DIY enthusiasts and professionals alike. Active participation can lead to faster diagnosis and repairs, ensuring the truck runs smoothly.

12.2 Video Tutorials and Guides

Video tutorials and guides provide hands-on visual instruction for understanding and working with Kenworth T880 wiring diagrams. Platforms like YouTube offer detailed walkthroughs of complex repairs and diagnostics. Many videos demonstrate how to interpret wiring diagrams, trace circuits, and repair common electrical issues. Some tutorials focus on specific systems, such as lighting or brake wiring, while others cover advanced troubleshooting techniques. These resources are particularly useful for visual learners and those new to truck electrical systems, offering step-by-step guidance to complement PDF manuals and written instructions.

12.4 Manufacturer Support Channels

Kenworth provides official support channels for accessing wiring diagrams and technical assistance. The manufacturer’s website offers downloadable PDF resources, including detailed wiring diagrams and repair manuals. Additionally, Kenworth dealerships and service centers offer expert guidance and troubleshooting support. These channels ensure access to accurate and up-to-date information, reducing errors in repairs. By utilizing manufacturer support, users can trust the reliability and comprehensiveness of the provided materials, ensuring safe and effective electrical system maintenance for the Kenworth T880.

The Kenworth T880 wiring diagram is crucial for efficient repairs and maintenance. Always follow safety guidelines and best practices, and consult official resources for accurate outcomes.

13.1 Recap of Key Points

The Kenworth T880 wiring diagram is essential for understanding and maintaining the truck’s electrical systems. Key points include the importance of using official manuals, identifying components, and following safety protocols. Regular inspections of wiring harnesses and connectors are critical to prevent issues. Tools like multimeters and circuit testers are vital for diagnostics. Common problems, such as blown fuses or short circuits, can be resolved with proper techniques. Always prioritize safety, disconnect the battery before repairs, and consult experts if unsure. These practices ensure efficient and safe electrical system maintenance.

13.2 Final Tips for Successful Wiring Repairs

Always cross-reference the wiring diagram with the actual truck setup to ensure accuracy. Use proper tools like multimeters and circuit testers for precise diagnostics. Test components before and after repairs to confirm functionality. Document any modifications for future reference. If unsure, consult experts or official manuals. Prioritize safety by disconnecting the battery and wearing protective gear. Regularly inspect wiring harnesses and connectors to prevent issues. By following these tips, you can ensure efficient and reliable electrical system repairs for your Kenworth T880.