LOTO (Lock Out Tag Out) is a safety procedure ensuring equipment isolation from energy sources․ It prevents unexpected startups, protecting workers during maintenance․ The process involves locks, tags, and verification to guarantee safety and compliance with regulations․

1․1 Definition and Purpose of LOTO

LOTO (Lock Out Tag Out) is a systematic safety procedure to isolate equipment from all energy sources․ It involves using locks and tags to ensure machinery remains shut down during maintenance․ The primary purpose of LOTO is to prevent accidental equipment startup, protecting workers from injuries caused by hazardous energy release․ This method is essential for safeguarding employees and ensuring compliance with workplace safety standards and regulations;

1․2 Importance of LOTO in Workplace Safety

LOTO is critical for preventing injuries and fatalities caused by unexpected equipment startup․ It ensures machinery remains de-energized during maintenance, protecting workers from hazardous energy․ Compliance with LOTO standards, such as OSHA 1910․147, is essential for legal and safety requirements․ By isolating energy sources, LOTO fosters a safer working environment, reducing risks and promoting a culture of safety․ Its implementation is vital for safeguarding employees and ensuring operational integrity in industrial settings․

Core Components of Lock Out Tag Out

Core components include energy isolation, risk assessment, and locks/tags․ These elements ensure safe de-energization and prevent accidental startups, protecting workers during maintenance tasks effectively․

2․1 Energy Isolation

Energy isolation is a critical step in LOTO, involving the physical disconnection of equipment from all energy sources․ This ensures machinery cannot operate unexpectedly․ Proper isolation requires identifying and controlling electrical, mechanical, hydraulic, and other energy sources․ Workers must verify energy absence before starting maintenance․ Effective isolation prevents accidents and ensures a safe working environment․ OSHA standards emphasize this step to protect employees from hazardous energy releases during equipment servicing․

2․2 Risk Assessment

Risk assessment is essential to identify hazards and determine necessary controls․ It evaluates the scope of work, energy sources, and potential risks․ This step ensures tailored safety measures, such as specific locks or tags, are applied․ A thorough assessment prevents oversights and enhances worker safety․ OSHA guidelines stress its importance in LOTO procedures to mitigate dangers during equipment maintenance or servicing․ Regular updates and reviews of risk assessments are crucial for maintaining effectiveness and compliance․

2․3 Locks and Tags

Locks and tags are critical components in LOTO procedures․ Locks physically prevent equipment startup, while tags provide clear warnings․ They must be durable, standardized, and securely attached․ Tags should include details like the worker’s name and date․ Multiple locks may be used on shared devices, ensuring all employees can secure equipment․ Proper application of locks and tags ensures compliance with safety standards and prevents accidental energization, safeguarding workers during maintenance activities․ Their use is mandated by OSHA regulations to ensure workplace safety․

Lock Out Tag Out Procedure Steps

LOTO procedures involve preparation, shutdown, isolating energy sources, applying locks/tags, verifying isolation, performing maintenance, and safely removing locks/tags to restore equipment operation․

3․1 Preparation and Planning

Preparation involves identifying equipment, energy sources, and necessary tools․ A detailed plan ensures all safety measures are in place; Personnel are informed, and risks are assessed to prevent hazards․ Proper documentation and review of procedures guarantee compliance with safety standards․

3․2 Shutdown of Equipment

Equipment shutdown requires following established stop procedures․ Operators must power down machinery, deactivate controllers, and ensure all functions cease․ Emergency stops may be used if necessary, and systems are transitioned to a safe state․ Proper shutdown is critical before isolation to prevent accidental start-ups during maintenance․

3․3 Isolation of Energy Sources

Isolation of energy sources involves physically disconnecting or de-energizing equipment from all potential energy supplies․ This includes electrical, hydraulic, pneumatic, and mechanical sources․ Physical disconnection, such as closing valves or removing fuse links, ensures no energy remains․ Isolation devices like ball valves or circuit breakers are used to separate equipment safely․ Verification of isolation is critical to confirm energy sources are fully disconnected before maintenance begins;

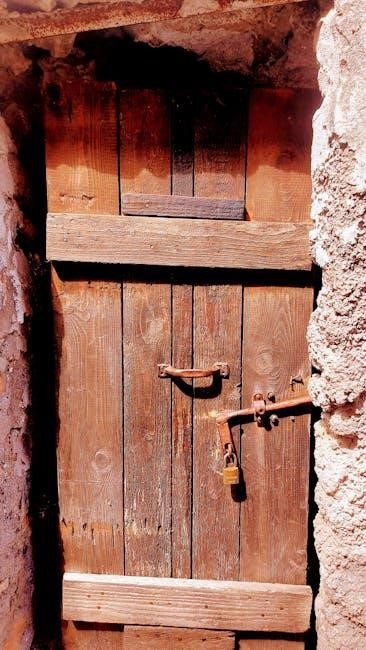

3․4 Application of Locks and Tags

The application of locks and tags is a critical step in the LOTO procedure․ Locks are applied to energy isolating devices to prevent accidental re-energization, while tags serve as visible warnings․ Each lock must be accompanied by a tag, clearly indicating the name of the person applying it and the reason for the lockout․ Multi-lock hasps can be used when multiple workers are involved, ensuring shared accountability․ Tags must be standardized and securely attached to ensure visibility and compliance with safety protocols․

3․5 Verification of Energy Isolation

Verification of energy isolation ensures equipment is safely de-energized․ After applying locks and tags, use test instruments like multimeters or pressure gauges to confirm zero energy․ All stored energy, such as hydraulics or capacitors, must be released․ Verify each energy source individually, and document the process․ This step is critical to prevent accidental startups and ensure worker safety․ Always follow established protocols to confirm isolation before starting maintenance․ Proper verification prevents potential hazards and ensures compliance with safety standards․

3․6 Completion of Maintenance

After completing maintenance tasks, ensure all work is inspected and approved․ Release stored energy and restore systems safely․ Document the completion and notify all affected personnel․ Verify energy sources are ready for reconnection․ Ensure locks and tags are removed only by authorized individuals․ Confirm the equipment is operational and safe before returning to service․ Properly document the process to maintain accountability and compliance with safety protocols․ This step ensures smooth transition back to normal operations while maintaining worker safety․

3․7 Removal of Locks and Tags

Removal of locks and tags must only occur after verifying all energy sources are safely isolated and maintenance is complete․ Ensure the area is secure and all personnel are informed․ The authorized person who applied the locks or tags should remove them, or they must have explicit permission to do so․ Double-check that no stored energy remains before restoring power․ Document the removal process to maintain accountability and safety․ This ensures a smooth transition back to operational status without risking worker safety․

Training and Compliance

LOTO training ensures employees understand procedures, roles, and responsibilities․ Compliance with OSHA standards is mandatory, reducing incidents and ensuring a safe working environment through proper protocols․

4․1 Employee Training Requirements

Employee training is critical for LOTO compliance․ Workers must understand energy isolation, lockout/tagout procedures, and their roles․ OSHA standards mandate training for both authorized and affected employees․ Regular updates ensure familiarity with equipment and protocols․ Training includes practical exercises to apply locks and tags correctly․ Employers must certify completion and provide refresher courses․ Proper training prevents accidents and ensures safe maintenance activities, aligning with regulatory requirements and company policies․ Continuous learning reinforces safety practices and accountability in the workplace․

4․2 Roles and Responsibilities

Clear roles and responsibilities are essential for LOTO effectiveness․ Authorized employees perform lockout/tagout, ensuring energy isolation․ Affected employees must understand procedures and not bypass safety measures․ Supervisors oversee compliance, while all staff adhere to safety protocols․ Accountability ensures safe work environments․ Roles are defined to prevent unauthorized actions and maintain operational safety․ Compliance with LOTO standards is mandatory for all involved, fostering a culture of shared responsibility and workplace safety․

4․3 OSHA Standards and Regulations

OSHA’s 29 CFR 1910․147 governs LOTO practices, requiring employers to develop and enforce energy control procedures․ These standards mandate training, proper use of locks and tags, and regular inspections․ Employers must ensure all equipment-specific risks are addressed, and workers are trained on LOTO protocols․ Non-compliance can lead to citations and penalties․ Adhering to OSHA regulations ensures workplace safety and legal compliance, safeguarding employees during equipment maintenance and servicing activities․

Devices Used in Lock Out Tag Out

The procedure utilizes locks, tags, and isolation devices to ensure energy isolation․ Multi-lock hasps allow multiple workers to secure equipment safely, promoting compliance and worker safety․

5․1 Types of Locks

Locks are essential for securing energy isolating devices․ Common types include padlocks, gate valve locks, and circuit breaker locks․ Each lock must be durable, uniquely identifiable, and specifically designed for LOTO․ Padlocks are often used with multi-lock hasps to allow multiple workers to apply personal locks․ Gate valve locks prevent valve operation, while circuit breaker locks secure breakers in the off position․ These locks ensure equipment remains de-energized, preventing accidental startups and protecting workers during maintenance tasks․

5․2 Types of Tags

Tags are critical for identifying locked-out equipment․ Common types include danger tags, caution tags, and do-not-operate tags․ Danger tags indicate immediate hazards, while caution tags warn of potential risks․ Tags must be durable, weather-resistant, and clearly state the reason for the lockout․ They are attached to locks or isolating devices to provide visual warnings․ Tags must be standardized and include relevant information, such as the worker’s name and date, ensuring clarity and compliance with safety regulations during maintenance activities․

5․3 Isolation Devices

Isolation devices are used to disconnect equipment from energy sources, ensuring safe maintenance․ Common types include ball valves, gate valves, and circuit breakers․ These devices physically interrupt energy flow, preventing equipment startup․ Proper selection and installation are crucial․ Multi-lock hasps allow multiple locks on a single device․ Having the correct types and quantities ensures compliance and safety during lockout/tagout procedures․ Regular inspection of isolation devices is essential to maintain their effectiveness in energy control and worker protection․

Group Lock Out Tag Out Procedure

Group LOTO involves multiple workers, each responsible for locking and tagging specific energy sources under supervision to ensure all are safely isolated, with clear communication and checks․

6․1 Multiple Workers Involved

When multiple workers are involved in LOTO, each must apply their own lock and tag to ensure personal accountability․ Clear communication and coordination are essential to guarantee all energy sources are safely isolated․ A designated supervisor oversees the process, verifying that all locks and tags are correctly applied before work begins․ This shared responsibility ensures no individual can mistakenly energize the equipment, enhancing overall safety and compliance with LOTO standards․

6․2 Shared Responsibility

Shared responsibility in LOTO ensures that all workers involved in the task are accountable for their safety and the safety of others․ Each worker must apply their own lock and tag, guaranteeing personal accountability․ Communication and coordination among team members are critical to ensure all energy sources are isolated․ A supervisor or authorized person oversees the process, verifying that all locks and tags are correctly applied․ This collective responsibility prevents accidental startup and ensures compliance with safety protocols․

Best Practices for LOTO

Adopting multi-lock hasps, standardizing procedures, and conducting regular audits are key best practices․ They ensure consistency, accountability, and compliance with safety regulations․

7․1 Use of Multi-Lock Hasps

Multi-lock hasps are essential for group lockout scenarios, allowing multiple workers to apply individual locks․ This ensures shared responsibility and prevents accidental equipment startup․ They accommodate several locks, enhancing safety by requiring all parties to remove their locks before reactivation․ Proper use of multi-lock hasps simplifies coordination and ensures compliance with safety protocols during maintenance tasks involving multiple personnel․

7․2 Standardization of Procedures

Standardizing LOTO procedures ensures consistency across all tasks and equipment․ It provides clear, uniform steps for shutdown, isolation, and lockout/tagout․ Employees receive identical training, reducing errors and improving compliance․ Standardization also simplifies audits and ensures documentation aligns with regulatory requirements․ Consistent procedures minimize confusion, enhance efficiency, and strengthen workplace safety, ensuring all personnel follow the same protocols for energy control and equipment maintenance․

7․3 Regular Audits and Inspections

Regular audits and inspections are crucial for maintaining LOTO compliance․ They ensure procedures are followed correctly, identify gaps, and verify the effectiveness of safety measures․ Inspections should be conducted by trained personnel, focusing on equipment, locks, tags, and documentation․ Corrective actions must be taken promptly to address any deficiencies․ These reviews promote accountability, uphold safety standards, and prevent potential incidents, ensuring a proactive approach to workplace safety and regulatory adherence․ Consistent oversight guarantees the integrity of LOTO practices․

Common Mistakes to Avoid

Common mistakes include neglecting to identify all energy sources, incomplete training, and improper use of locks and tags, which can lead to serious safety risks․

8․1 Failure to Identify All Energy Sources

One critical mistake is neglecting to identify all energy sources, including electrical, hydraulic, and pneumatic systems․ This oversight can lead to unexpected equipment startup, causing severe injuries or fatalities․ Proper risk assessments and detailed procedures are essential to ensure every energy source is accounted for and isolated․ Employees must be thoroughly trained to recognize and address all potential energy hazards before performing maintenance tasks․

8․2 Inadequate Training

Inadequate training is a common oversight, leading to improper LOTO procedures․ Employees must receive comprehensive training on identifying energy sources, applying locks and tags, and understanding their roles․ OSHA standards emphasize that workers must be proficient in LOTO to ensure safety․ Without proper training, workers may skip critical steps, increasing the risk of accidents․ Regular updates and refreshers are vital to maintain compliance and prevent lapses in safety protocols․

8․3 Improper Use of Locks and Tags

Improper use of locks and tags significantly compromises safety․ Tags must be securely attached and clearly visible, while locks should be applied correctly to prevent accidental removal․ Using unauthorized or damaged devices can lead to equipment energization during maintenance․ Ensuring all locks and tags meet OSHA standards is crucial․ Proper training and regular inspections are essential to prevent such mistakes, safeguarding employees from potential hazards associated with energized equipment․

Importance of Documentation

Documentation is essential for compliance and accountability․ It ensures procedures are followed, training is verified, and incidents are recorded․ Proper records maintain safety standards and audit preparedness․

9․1 Record Keeping

Record keeping is a critical component of the LOTO process․ It involves maintaining detailed documentation of all lockout and tagout activities, including the identification of energy sources, the application of locks and tags, and the verification of energy isolation․ Proper records must be kept for each equipment and procedure, ensuring compliance with safety standards and regulations․ This documentation serves as evidence of adherence to protocols and provides valuable information for audits and incident investigations․

9․2 Incident Reporting

Incident reporting is essential for documenting any unintended events during LOTO procedures․ It involves recording details of accidents, near misses, or violations of safety protocols․ Reports must include the root cause, affected equipment, and corrective actions taken․ Timely and accurate reporting ensures transparency, accountability, and continuous improvement of safety measures, helping to prevent future incidents and maintaining a safe working environment․

Tools and Equipment for LOTO

LOTO involves using locks, tags, and isolation devices to secure equipment․ Personal protective equipment (PPE) is also essential․ These tools ensure compliance with safety standards and prevent unauthorized startups․

10․1 Lockout Devices

Lockout devices are critical in LOTO procedures․ They physically prevent equipment activation by blocking energy sources like valves or breakers․ Common types include padlocks, hasps, and scissor locks․ These devices ensure machinery remains inactive during maintenance․ Multi-lock hasps allow multiple workers to apply individual locks, enhancing safety․ Proper selection and application of these devices are essential for compliance with OSHA standards and workplace safety protocols․ They are durable and designed to withstand harsh environments, ensuring reliable protection for employees․

10․2 Tagout Devices

Tagout devices are essential components of the LOTO procedure․ They serve as visible warnings that equipment is unsafe to operate․ Tags are securely attached to equipment or energy isolating devices, indicating maintenance is in progress․ They must be durable, weather-resistant, and clearly marked with warnings․ Tags should include details like the worker’s name and date to ensure accountability․ While they don’t provide physical restraint, they complement lockout devices by alerting others not to restart machinery․ Proper use of tagout devices is critical for compliance with OSHA standards and workplace safety․

10․3 PPE and Safety Gear

Personal Protective Equipment (PPE) and safety gear are vital in LOTO procedures․ Workers must wear appropriate PPE, including gloves, safety glasses, and high-visibility clothing, to protect themselves from potential hazards․ Hard hats and steel-toe boots are also essential when working near heavy machinery․ Proper PPE ensures compliance with safety regulations and minimizes risks during maintenance activities․ Employers must provide suitable PPE and ensure employees use it correctly, reinforcing a culture of safety and adherence to LOTO protocols․

Steps to Ensure Compliance

Regular audits, updated procedures, and employee feedback ensure compliance․ Continuous improvement through training and adherence to OSHA standards guarantees a safe and efficient LOTO process․

11․1 Regular Updates to Procedures

Regular updates to LOTO procedures ensure alignment with changing OSHA standards and operational needs․ Reviews involve feedback from employees and supervisors to address new equipment or processes․ Updates are documented, approved, and communicated to all affected personnel․ This ensures procedures remain effective and relevant, reducing compliance risks and enhancing workplace safety․ Continuous improvement fosters a culture of safety and accountability․

11․2 Employee Feedback

Employee feedback is crucial for refining LOTO procedures․ Workers involved in maintenance provide insights on challenges and suggest improvements․ Regular surveys and meetings ensure their voices are heard․ This collaborative approach enhances procedure effectiveness and compliance․ By involving employees, organizations foster a safety-focused culture and ensure procedures are practical and user-friendly, ultimately reducing risks and improving overall safety standards․

11․3 Continuous Improvement

Continuous improvement ensures LOTO procedures remain effective․ Regular audits and incident reviews identify areas for enhancement․ Updates are made to reflect new technologies and industry best practices․ Training programs are refined based on employee feedback and changing regulations․ This proactive approach ensures ongoing compliance and safety, safeguarding employees and equipment․ Continuous improvement is essential for maintaining a robust LOTO program that adapts to evolving workplace needs and standards․

LOTO ensures workplace safety by preventing equipment startup during maintenance․ Compliance with OSHA standards protects employees from hazardous energy, making LOTO essential for safe operations and regulatory adherence․

12․1 Summary of Key Points

LOTO ensures workplace safety by controlling hazardous energy․ Key steps include identifying energy sources, isolating equipment, and applying locks and tags․ Verification is critical to confirm energy isolation․ Compliance with OSHA standards and regular training are essential․ Proper documentation and continuous improvement enhance safety․ Group LOTO and multi-lock hasps address shared responsibilities․ Avoiding mistakes like failing to identify energy sources is vital․ LOTO safeguards employees during maintenance, ensuring safe and efficient operations while adhering to regulatory requirements․

12․2 Final Thoughts on LOTO

LOTO is a fundamental safety protocol essential for protecting workers during equipment maintenance․ It ensures energy isolation through locks and tags, preventing accidental startups․ Adhering to OSHA standards is crucial, and consistent application guarantees effectiveness․ By prioritizing LOTO, organizations not only enhance safety but also maintain operational efficiency, fostering a secure working environment for all employees involved in maintenance activities․